End-to-End Development Pipeline

Additive Concept Engineering & Systems Architecture

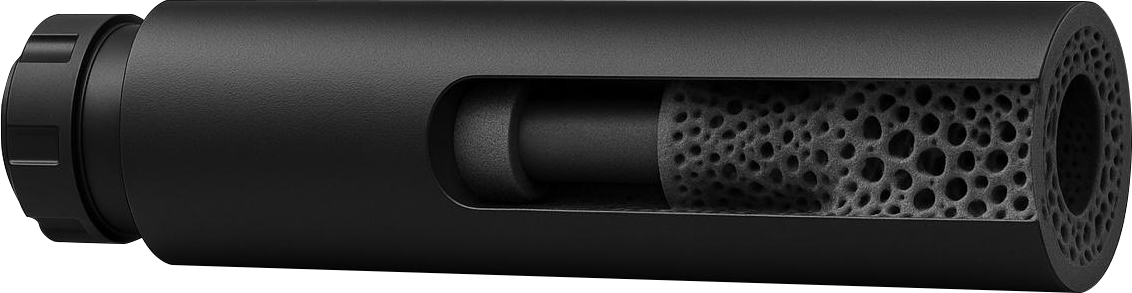

Wain develops defense technology concepts engineered from inception for additive manufacturing. By applying topology optimization, multi-scale lattice structures, and functionally graded porosity, our designs achieve geometries beyond the limits of conventional machining. Internal architectures are digitally modeled to manage pressure, thermal transfer, vibration, and energy absorption, delivering performance gains across weapons systems, aerospace platforms, armor solutions, and other mission critical applications. Leveraging advanced powder metallurgy and prototype alloy systems, concepts are built for maximum strength-to-weight efficiency, longevity under extreme loads, and repeatability at scale. Every design is architected within global jurisdictional frameworks, ensuring compliance while redefining the boundaries of defense engineering.

Engineering & Applied Development

Ideas progress into engineering, where Wain’s teams integrate mechanical, structural, and material science disciplines into refined, testable designs. Global engineering resources are deployed strategically; where ITAR or other export-controlled regulations apply, projects are conducted within segregated, jurisdiction specific teams, maintaining airtight compliance while still advancing innovation at pace. Advanced simulations and multi-domain analysis ensure every design is optimized for reliability, survivability, and operational superiority.

Advanced Material Science Integration

Performance is amplified at the material level. Wain’s global material science teams research and develop advanced alloys, composites, and high temperature resistant supermetals. When projects fall under ITAR or comparable frameworks, restricted material data and designs remain strictly within controlled jurisdictions, ensuring secure and compliant integration of material innovations. These breakthroughs expand performance envelopes and enable longer system lifecycles in the harshest environments.

Prototyping & Performance Validation

Rapid prototyping transforms concepts into reality. Through additive manufacturing, advanced machining, and hybrid build techniques, Wain delivers functional prototypes in accelerated timelines. Prototypes are stress-tested under operationally relevant conditions to validate performance, bridging the gap between theoretical design and proven capability, all while ensuring compliance with regional manufacturing and export restrictions.

Manufacturing & Production Readiness

Validated systems move seamlessly into production. Wain’s distributed manufacturing infrastructure supports pilot runs and full-scale industrialization, with compliance based separation of production lines for ITAR governed versus unrestricted projects. Digital manufacturing workflows, rigorous quality assurance, and NATO-aligned standards ensure every system is built to exacting tolerances and delivered mission-ready for allied partners.

Special Mission Projects Division (TSF)

Wain operates a dedicated global engineering unit focused exclusively on Special Mission Projects. This highly compartmentalized division is structured to support Tier 1 military and special mission units across NATO and allied nations. Access is restricted to established military and government channels, ensuring the integrity and security of all engagements.

The TSF division develops bespoke solutions ranging from advanced weapon system integrations and ultra-specialized material applications to nexgen suppressor and platform technologies tailored to the unique requirements of elite operational teams. Operating under strict need-to-know protocols, with dedicated secure facilities and segregated data environments, the division ensures that mission critical innovations remain both uncompromised and battlefield ready.

TSF reflects Wain’s unwavering commitment to supporting global special operations with technologies that deliver decisive, real-world advantage where it matters most.

The TSF division develops bespoke solutions ranging from advanced weapon system integrations and ultra-specialized material applications to nexgen suppressor and platform technologies tailored to the unique requirements of elite operational teams. Operating under strict need-to-know protocols, with dedicated secure facilities and segregated data environments, the division ensures that mission critical innovations remain both uncompromised and battlefield ready.

TSF reflects Wain’s unwavering commitment to supporting global special operations with technologies that deliver decisive, real-world advantage where it matters most.